Small businesses are constantly battling rising operational costs, and logistics expenses can quickly become a significant financial drain! Did you know that logistics costs can eat up to 10-25% of a company’s total revenue?

In today’s competitive marketplace, finding smart ways to reduce these expenses isn’t just a nice-to-have—it’s a critical survival strategy.

Whether you’re a startup struggling with tight margins or an established small business looking to maximize profitability, this guide will walk you through actionable, game-changing approaches to trimming your logistics expenses.

Here I am sharing my experiences and knowledge of study and research for a comprehensive cost-cutting guidelines.

Analyze and Optimize Your Current Logistics Spending: A Small Business Guide

Let me walk you through the critical process of understanding and slashing your logistics expenses.

As someone who’s helped numerous small businesses transform their logistics spending, I can tell you this: most companies are bleeding money without even realizing it!

Why a Logistics Cost Audit Matters

Imagine your logistics expenses as a leaky bucket. Every untracked dollar is water dripping away, slowly but steadily impacting your business’s financial health.

A comprehensive logistics cost audit is like plugging those holes, giving you crystal-clear visibility into where your money is actually going.

The Hidden Cost Landscape

Logistics expenses aren’t just about shipping costs. They’re a complex web of interconnected expenses that can silently drain your profitability.

Here’s a breakdown of what we’re really talking about:

| Expense Category | Typical Hidden Costs | Potential Annual Impact |

|---|---|---|

| Transportation | Fuel surcharges, idle truck time | $5,000 – $25,000 |

| Warehousing | Inefficient space utilization | $3,000 – $15,000 |

| Inventory | Overstocking, obsolescence | $2,500 – $10,000 |

| Administrative | Manual processing, errors | $1,500 – $7,500 |

Practical Steps for a Comprehensive Logistics Cost Audit

1. Gather Your Financial Evidence

- Collect ALL shipping invoices from the past 12 months

- Pull transportation contracts and carrier agreements

- Export warehouse management system reports

- Review inventory purchasing and holding records

- Compile administrative overhead related to logistics

2. Technology: Your Audit Superpower

Real-time expense tracking isn’t a luxury—it’s a necessity. Here are my top technology recommendations:

Recommended Tracking Tools:

- FreightView (Transportation management)

- ShipStation (Shipping cost analysis)

- Oracle NetSuite (Comprehensive logistics tracking)

- Cin7 (Inventory and logistics integration)

3. Uncover Hidden Inefficiencies

Most businesses overlook these sneaky expense areas:

- Partial truck load (PTL) shipping inefficiencies

- Unnecessary expedited shipping charges

- Redundant inventory holding costs

- Manual data entry and reconciliation time

- Frequent small-batch ordering

Pro Tips for Expense Identification

✅ Use the 80/20 rule: Focus on the 20% of expenses causing 80% of your costs

✅ Compare month-to-month and year-over-year spending patterns

✅ Look for consistent outliers in your expense reports

✅ Calculate your total landed cost, not just shipping expenses

Industry Benchmarking: How Do You Compare?

Small business logistics expenses typically range between 5-10% of total revenue. If you’re higher, it’s time for serious optimization! Here’s a quick benchmark table:

| Business Size | Typical Logistics Expense Ratio |

|---|---|

| Micro (0-10 employees) | 8-12% |

| Small (11-50 employees) | 6-10% |

| Medium (51-250 employees) | 4-8% |

Creating Your Expense Breakdown

When categorizing expenses, be ruthlessly specific:

- Direct Transportation Costs (This cost includes fuel expenses, vehicle maintenance, driver wages, tolls, waiting fees, and any fees charged by transport providers. These costs directly relate to the movement of the goods from one location to another.)

- Warehousing Expenses (Warehousing costs refer to the fees associated with operating a warehouse, such as rent, utilities, labor, insurance, maintenance, and taxes. It also includes the cost of goods stored in the warehouse, including the cost of inventory control, order fulfillment, and other related services.)

- Inventory Holding Costs (Inventory holding sum = capital cost + inventory service cost + risk cost + storage cost.)

- Packaging Materials Cost (Primary Packing Material are for holding the product, keeping the contents clean, fresh, sterile and safe for the intended shelf life and sale. Packaging cost = (Cost of materials + Cost of labor) x Quantity. The cost of materials includes things like boxes, tape, labels, cushioning etc.)

- Technology and Software (The cost includes software itself, its installation, labor fees, and taxes.)

- Labor Costs (Cost of labor is the amount paid by an employer to cover an employee’s wages and benefits, plus related payroll taxes and benefits.)

- Administrative Overhead (The overhead costs are the indirect expenses that are essential for the operational management of the whole logistics system.)

Key Performance Indicators (KPIs) to Track

- Freight cost per unit (Calculation of freight cost per unit involves two fundamental steps: Data Collection: Collect all relevant data, primarily total freight cost and the total number of units in the shipment. Performing the Calculation: Divide the total freight cost by the total number of units to get the freight cost per unit.

- Inventory turnover rate (Inventory turnover is the rate that inventory stock is sold, or used, and replaced. The inventory turnover rate is calculated by dividing the cost of goods by average inventory for the same period. A higher ratio tends to point to strong sales and a lower one to weak sales.)

- Order fulfillment time (Total order cycle time is calculated with the formula “time the purchase order was received by customer” minus the “time the purchase order was placed” divided by the “total number of orders shipped.” It could also be calculated as: order cycle time = (delivery date – order date) / total number of orders shipped.)

- Transportation spend as a percentage of revenue (This measure calculates total annual transportation cost as a percentage of revenue. Transportation Expense as a Percentage of Total Revenue measures the transportation-related expense (fuel, fleet management costs, driver labor, etc.)

- Warehouse capacity utilization (Add up the volume of all the products that are stored in the warehouse and divide it by the total warehouse space store capacity. This will be the final warehouse space utilization number.)

Action Items

A logistics cost audit isn’t a one-time event—it’s an ongoing process. Schedule quarterly deep-dive reviews and stay proactive. Every percentage point you reduce in logistics expenses goes directly to your bottom line.

Your next steps:

- Collect all relevant financial documents

- Choose 2-3 tracking technologies

- Conduct your first comprehensive audit

- Develop a reduction strategy

- Implement and continuously monitor

As a logistics professional, I believe knowledge is power—and in logistics, knowledge means profitability!

Leverage Technology for Logistics Cost Reduction: Your Digital Transformation Roadmap

Let me take you on a journey through the technological landscape that can revolutionize your small business logistics. In my years of consulting, I’ve seen how the right technology can turn logistics from a cost center into a competitive advantage!

The Technology Transformation: More Than Just Software

Technology isn’t just about buying fancy tools—it’s about creating a smart, interconnected logistics ecosystem that works harder, faster, and more efficiently than ever before. Think of it like upgrading from a bicycle to a high-performance electric bike that practically pedals itself!

Technology Impact: By the Numbers

| Technology Area | Potential Cost Savings | Efficiency Improvement |

|---|---|---|

| Route Optimization | 15-30% transportation costs | 25-40% route efficiency |

| AI Inventory Management | 20-35% inventory holding costs | 40-50% demand forecasting accuracy |

| Process Automation | 25-45% operational expenses | 60-75% process speed |

Deep Dive: Strategic Technology Implementation

1. Logistics Management Software: Your Digital Command Center

Top Recommendation: Cloud-Based Integrated Solutions

Key Selection Criteria:

- Real-time tracking capabilities

- Seamless integration potential

- Scalability for future growth

- User-friendly interface

- Robust reporting features

Practical Implementation Tip

Start with a pilot program. Don’t try to digitize everything overnight. Choose one critical process, implement the technology, measure results, and then expand.

2. Route Optimization: Turning Miles into Savings

AI-powered route optimization isn’t just about finding the shortest path—it’s about intelligent decision-making that considers:

- Real-time traffic conditions

- Fuel efficiency

- Delivery time windows

- Vehicle capacity

- Cost constraints

Recommended Tools:

3. AI-Powered Inventory Management: Predictive Intelligence

Imagine having a crystal ball that accurately predicts your inventory needs. That’s what AI-powered systems do! These smart systems:

- Analyze historical sales data

- Predict future demand

- Minimize overstocking and stockouts

- Automate reordering processes

- Provide real-time inventory insights

4. Cloud-Based Logistics Platforms: Flexibility Meets Power

Why cloud platforms? Because they offer:

- Accessibility from anywhere

- Automatic updates

- Lower infrastructure costs

- Instant scalability

- Enhanced collaboration

Top Cloud Logistics Platforms:

5. Process Automation: Your Digital Workforce

Automation isn’t about replacing humans—it’s about empowering them to focus on high-value tasks.

Processes Ripe for Automation:

- Invoice processing

- Shipment tracking

- Inventory counting

- Reporting

- Communication workflows

Technology Integration Roadmap

Professional Tips for Successful Technology Adoption

✅ Involve your team in technology selection

✅ Prioritize user-friendly interfaces

✅ Invest in comprehensive training

✅ Start small and scale gradually

✅ Measure and celebrate quick wins

Cost-Benefit Analysis Framework

Before implementing any technology, ask:

- What’s the implementation cost?

- What’s the potential ROI?

- How long until break-even?

- What’s the long-term scalability?

Warning Signs You Need Technology Intervention

Indicators of Technological Stagnation:

- Manual data entry consuming hours

- Frequent shipping errors

- Inability to track inventory accurately

- Lack of real-time visibility

- Consistently missed delivery windows

Technology as an Investment

Remember, technology in logistics isn’t an expense—it’s an investment in your business’s future. Every dollar spent on smart technology can return multiple times over through efficiency, accuracy, and strategic insights.

Negotiating Better Shipping Rates: Your Small Business Survival Guide

Let me reveal on shipping contract negotiations—a world that can seem intimidating but is actually your secret weapon for massive cost savings. As someone who’s helped dozens of small businesses slash their shipping expenses, I’m about to share strategies that most companies don’t even know exist!

The Real Truth About Shipping Rates

Most small business owners believe shipping rates are fixed. Spoiler alert: They’re not! Shipping rates are surprisingly negotiable, and with the right approach, you can dramatically reduce your transportation costs.

Shipping Cost Landscape for Small Businesses

| Business Shipping Volume | Potential Negotiation Leverage | Average Cost Reduction |

|---|---|---|

| Low Volume (0-500 shipments/year) | 5-10% | $500 – $2,000 annually |

| Medium Volume (501-2,000 shipments/year) | 10-20% | $2,500 – $8,000 annually |

| High Volume (2,001-5,000 shipments/year) | 20-35% | $8,500 – $20,000 annually |

Strategic Negotiation Approaches

1. Understanding the Shipping Contract Battlefield

Shipping contracts are like complex chess games. You need to understand:

- Base rates (The base rate is the foundational cost of shipping freight, determined by carriers based on factors like distance, transport mode, and type of goods.)

- Dimensional weight pricing (DIM pricing refers to shipping costs that factor in the dimensional weight (DIM) into the overall price it will cost to ship a package. If the DIM weight exceeds the actual weight of the item, the DIM weight is then used to calculate the price instead. Volumetric weight pricing (VWP) is its another name.)

- Accessorial charges (Accessorial charges are fees that freight carriers bill to their customers when additional transportation services, such as unpacking, lift gates, and detentions are used to complete a delivery. These additional services are not initially covered in the base rate fee and are added to your freight invoice once billed.)

- Fuel surcharges (A Fuel Surcharge is an additional fee imposed by transportation companies to cover the fluctuating costs of fuel. It is typically linked to an index that tracks fuel prices, ensuring that charges adjust in response to changes in the cost of diesel, gasoline, or other fuels.)

- Minimum charge thresholds (Absolute Minimum Charge– the minimum charge after application of all pricing terms.

- Service Contract benefit (A service contract exists to ensure that your business and customer stay on the same page regarding the previously discussed terms and conditions.)

As a logistics professional, I have experienced that carriers have more flexibility in pricing than they let on. Your goal is to expose and exploit those flexibility points.

2. Shipment Consolidation: Your Cost-Cutting Secret Weapon

Consolidation isn’t just about combining packages—it’s a strategic approach to reduce per-unit shipping costs.

Consolidation Strategies:

- Group shipments to same geographic regions

- Use multi-stop delivery routes

- Implement shared transportation solutions

- Negotiate multi-package discounts

- Coordinate delivery schedules

Consolidation Impact Calculator Example

- Single Shipment Cost: $15

- Consolidated Shipment Cost: $8

- Monthly Shipments: 100

- Annual Savings: $8,400

3. Carrier Comparison: Don’t Put All Eggs in One Basket

| Carrier | Strengths | Best For | Typical Discounts |

|---|---|---|---|

| UPS | Extensive network | Business-to-business | 20-30% |

| FedEx | Fast international | Time-sensitive shipments | 15-25% |

| USPS | Local delivery | Lightweight packages | 10-20% |

| Regional Carriers | Cost-effective | Local/state shipments | 25-40% |

Negotiation Tactics for Each Carrier

- Request detailed rate sheets

- Compare accessorial charges

- Understand peak/non-peak pricing

- Negotiate volume-based discounts

- Explore contract-specific incentives

4. Volume Discount Strategies

Shipping volume is your negotiation superpower. Here’s how to leverage it:

Volume Discount Tiers:

- Bronze (100-500 shipments/year)

- Silver (501-1,500 shipments/year)

- Gold (1,501-5,000 shipments/year)

- Platinum (5,000+ shipments/year)

Each tier unlocks progressively better rates and perks:

- Lower base rates

- Reduced fuel surcharges

- Waived accessorial fees

- Dedicated account management

- Faster claims processing

5. Regional and Local Shipping Alternatives

Don’t overlook smaller, regional carriers. They often provide:

- More personalized service

- Lower rates

- Faster local delivery

- More flexible negotiations

Top Regional Carrier Networks:

- OnTrac (Western US)

- LaserShip (Eastern US)

- LSO (Southwest)

- Spee-Dee Delivery (Midwest)

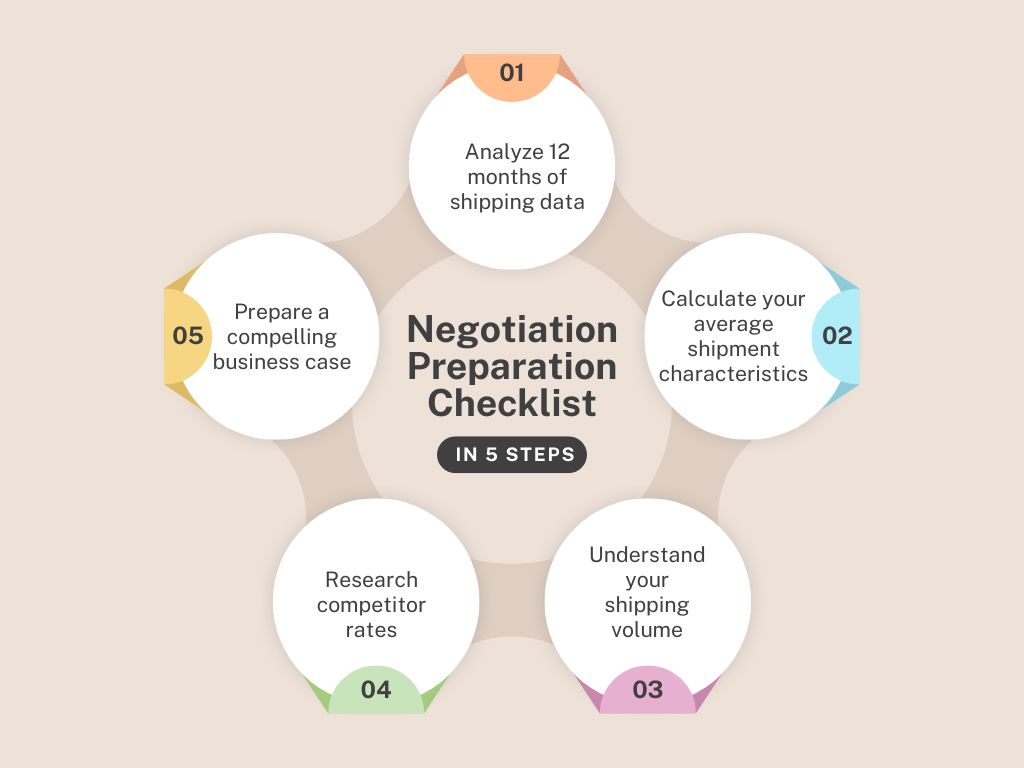

Negotiation Preparation Checklist

Red Flags in Shipping Contracts

Warning Signs to Avoid:

- Unclear accessorial charges

- Rigid rate structures

- No volume discount options

- Excessive penalty clauses

- Limited service guarantee

Psychological Negotiation Tips

- Be confident but respectful

- Show you’ve done your homework

- Demonstrate your potential as a long-term partner

- Be willing to walk away

- Request trial periods for new rates

Technology Assists

Recommended Negotiation Tools:

- Shippo (Rate Comparison)

- ShipStation (Shipping Analytics)

- Freightos (Carrier Negotiations)

Your Actionable Roadmap

- Compile comprehensive shipping history

- Research alternative carriers

- Calculate potential savings

- Prepare negotiation strategy

- Schedule carrier discussions

- Negotiate confidently

- Implement and monitor results

Every percentage point you save in shipping is pure profit. You’re not just cutting costs—you’re building a more competitive business!

Inventory Management Mastery: Turn Your Stock into a Strategic Asset

Let me share a game-changing truth: Inventory isn’t just a collection of products—it’s your business’s financial heartbeat. As someone who’s helped numerous small businesses transform their inventory from a cost center to a profit accelerator, I’m about to unpack the strategies that separate successful businesses from those constantly struggling with stock management.

The True Cost of Poor Inventory Management

Most business owners don’t realize the hidden expenses lurking in their inventory. Let’s break down the financial impact:

| Inventory Management Issue | Annual Cost Impact | Potential Waste |

|---|---|---|

| Overstocking | 25-40% of inventory value | Tied-up capital, storage costs |

| Understocking | 10-20% lost sales potential | Missed revenue opportunities |

| Inefficient Tracking | 15-30% operational inefficiency | Increased labor and error costs |

Just-in-Time (JIT) Inventory: Your Lean Strategy Superpower

What JIT Really Means

Think of JIT like a precision dance. Instead of hoarding inventory like a squirrel storing nuts for winter, you’re receiving exactly what you need, precisely when you need it. It’s about creating an ultra-responsive supply chain that moves with lightning speed and razor-sharp precision.

Key JIT Principles:

- Minimize inventory holding

- Reduce storage costs

- Increase cash flow

- Improve product freshness

- Minimize waste

Predictive Analytics: Your Crystal Ball of Demand

Predictive analytics isn’t magic—it’s strategic intelligence. By leveraging data, you can:

- Forecast demand with 80-95% accuracy

- Identify seasonal trends

- Predict customer behavior

- Optimize stock levels

- Reduce inventory carrying costs

Top Predictive Analytics Tools

- IBM Watson Supply Chain Insights

- SAP Integrated Business Planning

- Oracle Demand Management Cloud

- Prevedere Predictive Analytics

Warehouse Storage Cost Reduction Strategies

The Storage Cost Breakdown

- Rent/Mortgage: 40-50%

- Utilities: 15-25%

- Labor: 20-30%

- Equipment: 5-15%

Cost-Cutting Approaches:

- Vertical storage solutions

- Automated storage systems

- Shared warehousing

- Modular warehouse design

- Zone-based organization

Overstocking vs. Understocking: The Balancing Act

Overstocking Red Flags

Signs You’re Overstocked:

- Products sitting untouched for 3+ months

- Storage costs exceeding 15% of product value

- Difficulty tracking inventory

- Frequent clearance sales

- Obsolete product accumulation

Understocking Warning Signs

Indicators of Insufficient Stock:

- Frequent stockouts

- Lost sales opportunities

- Customer complaints

- Rushed emergency ordering

- Increased expedited shipping costs

Lean Inventory Management Practices

The 5S Methodology

- Sort: Remove unnecessary items

- Set in Order: Organize efficiently

- Shine: Keep workspace clean

- Standardize: Create consistent processes

- Sustain: Continuous improvement

Technology Integration

Recommended Inventory Management Technologies:

- Zoho Inventory

- TradeGecko

- NetSuite

- Fishbowl Inventory

Practical Implementation Roadmap

Conduct Comprehensive Inventory Audit

- Analyze current stock levels

- Identify slow-moving items

- Map current storage processes

Develop Predictive Forecasting Model

- Collect historical sales data

- Identify seasonal patterns

- Create baseline demand predictions

Implement Technology Solutions

- Choose scalable inventory management software

- Train team on new systems

- Create standard operating procedures

Establish Continuous Improvement Mechanism

- Monthly inventory reviews

- Quarterly process optimization

- Regular technology updates

Cost-Saving Calculation Framework

Potential Annual Savings Breakdown

- Reduced Storage Costs: 20-35%

- Improved Cash Flow: 15-25%

- Decreased Waste: 10-20%

- Operational Efficiency: 25-40%

Professional Tips for Inventory Success

Inventory management isn’t about perfection—it’s about continuous improvement. Every small optimization compounds into significant strategic advantages.

Strategic Warehouse and Transportation Management: Your Competitive Advantage Roadmap

Let me reveal on a transformation that can make or break your small business logistics. As someone who’s guided companies through complex logistics challenges, I’m about to share strategies that turn your warehouse and transportation from a cost center into a strategic powerhouse!

The Logistics Landscape: More Than Just Moving Boxes

Most businesses see warehousing and transportation as necessary evils. Smart companies? They see them as competitive differentiators that can dramatically impact bottom-line performance.

Financial Impact of Strategic Management

| Optimization Area | Potential Cost Savings | Efficiency Improvement |

|---|---|---|

| Warehouse Design | 15-30% operational costs | 25-40% space utilization |

| Transportation Optimization | 20-35% shipping expenses | 40-55% route efficiency |

| Cross-Docking | 10-25% handling costs | 30-45% processing speed |

1. Warehouse Location and Design: Your Strategic Foundation

Location Selection Criteria

Key Factors to Consider:

- Proximity to key markets

- Transportation infrastructure

- Labor availability

- Real estate costs

- Proximity to suppliers

Warehouse Design Optimization Strategies

- Implement vertical storage solutions

- Use modular, flexible layouts

- Optimize picking routes

- Invest in automation

- Create multi-purpose zones

Design Efficiency Calculator

- Traditional Warehouse Utilization: 60-70%

- Optimized Warehouse Utilization: 85-95%

- Potential Space Savings: 20-35%

2. Cross-Docking: The Speed Demon of Logistics

Think of cross-docking like a high-speed relay race for your products. Goods arrive, get sorted, and immediately shipped out—minimizing storage time and handling costs.

Cross-Docking Benefits:

- Reduced warehouse storage needs

- Faster product movement

- Lower handling costs

- Improved inventory turnover

- Enhanced supply chain responsiveness

Implementation Stages

- Assess product compatibility

- Develop sorting infrastructure

- Create real-time tracking systems

- Train team on new processes

- Continuously optimize workflows

3. Shared Warehousing: Collaborative Cost Reduction

Shared warehousing is like carpooling for your inventory. By splitting infrastructure costs, you gain:

- Reduced fixed expenses

- Scalable storage solutions

- Access to advanced technologies

- Flexible capacity management

- Lower capital investment

Top Shared Warehousing Platforms

4. Load Planning and Truck Capacity Optimization

Load planning is a complex puzzle of maximizing space, weight, and efficiency.

Optimization Techniques:

- Use load optimization software

- Implement cube utilization strategies

- Balance weight distribution

- Consider multi-stop routing

- Explore partial load opportunities

Capacity Utilization Metrics

- Average Truck Utilization (Traditional): 65-75%

- Optimized Truck Utilization: 85-95%

- Potential Savings: 15-25% per shipment

5. Alternative Transportation Modes

Don’t put all your transportation eggs in one basket! Explore diverse shipping strategies:

Transportation Mode Comparison:

| Mode | Cost Efficiency | Speed | Best For |

|---|---|---|---|

| Truck | Medium | Fast | Regional, Flexible |

| Rail | Low | Moderate | Bulk, Long-Distance |

| Intermodal | Low-Medium | Moderate | Complex Routes |

| Air | High | Very Fast | Time-Sensitive |

| Hybrid Solutions | Varies | Balanced | Customized Needs |

Technology Integration Toolkit

Recommended Tools:

- Manhattan Associates TMS

- Blue Yonder Logistics

- Oracle Transportation Management

- SAP Logistics Execution

- Descartes Routing Software

Comprehensive Implementation Roadmap

- Conduct Logistics Audit

- Analyze current processes

- Identify bottlenecks

- Map existing infrastructure

2. Develop Optimization Strategy

- Set clear goals

- Create phased implementation plan

- Budget for technology investments

3. Technology and Process Integration

- Select appropriate tools

- Train team members

- Create standard operating procedures

4. Continuous Improvement Mechanism

- Monthly performance reviews

- Quarterly process optimization

- Stay updated on emerging technologies

Sustainable Logistics: Transforming Environmental Responsibility into Business Advantage

Let me share a powerful truth: Sustainability isn’t just an environmental buzzword—it’s a strategic business opportunity that can simultaneously reduce costs, attract customers, and create a positive impact on our planet.

As someone who’s guided businesses through green transformation, I’m excited to unveil how sustainable logistics can become your competitive edge!

The Real Economics of Sustainable Logistics

Most businesses see sustainability as an expense. The smart ones see it as an investment. Let’s break down the financial and environmental mathematics:

| Sustainability Strategy | Cost Savings | Carbon Reduction |

|---|---|---|

| Efficient Routing | 15-30% fuel costs | 20-40% emissions |

| Energy-Efficient Vehicles | 25-45% operational expenses | 50-70% carbon footprint |

| Packaging Optimization | 10-25% packaging costs | 30-50% waste reduction |

| Carbon-Neutral Shipping | Varies by implementation | Near-zero net emissions |

Why Sustainability Matters More Than Ever

The Business Case for Going Green

- 73% of consumers prefer environmentally responsible companies

- Sustainable practices can reduce operational costs

- Government incentives are increasing

- Brand reputation gets a significant boost

- Attracts environmentally conscious talent and customers

1. Fuel Consumption Reduction: Smart Routing Strategies

Efficient routing is like a financial and environmental superpower. By optimizing every mile, you:

- Decrease fuel expenses

- Reduce carbon emissions

- Improve delivery times

- Enhance overall operational efficiency

Routing Optimization Techniques

- Use AI-powered route planning software

- Implement multi-stop delivery strategies

- Minimize empty return trips

- Utilize real-time traffic data

- Prioritize shortest, most efficient routes

Top Routing Optimization Tools

- OptimoRoute

- Route4Me

- WorkWave Route Manager

- Routific

2. Energy-Efficient Transportation: The Future is Green

Transportation isn’t just about moving goods—it’s about moving them intelligently and sustainably.

Green Transportation Options:

- Electric vehicles

- Hybrid delivery trucks

- Compressed natural gas (CNG) vehicles

- Hydrogen fuel cell vehicles

- Aerodynamic vehicle designs

Investment Breakdown

| Vehicle Type | Initial Cost | Annual Savings | Emission Reduction |

|---|---|---|---|

| Electric Van | Higher upfront | 40-60% fuel costs | 70-90% emissions |

| Hybrid Truck | Moderate | 25-45% fuel costs | 50-70% emissions |

| CNG Vehicle | Moderate | 30-50% fuel costs | 60-80% emissions |

3. Packaging Waste Minimization: Less is More

Packaging isn’t just a protective layer—it’s an environmental statement.

Sustainable Packaging Strategies:

- Use recycled materials

- Minimize packaging size

- Implement reusable packaging systems

- Choose biodegradable options

- Design for easy recycling

Packaging Impact Calculator

- Traditional Packaging Waste: 30-50 grams/shipment

- Optimized Packaging: 10-20 grams/shipment

- Potential Reduction: 60-70% waste

4. Carbon-Neutral Shipping: Beyond Offset

Carbon-neutral shipping goes beyond simply purchasing offsets. It’s a comprehensive approach to reducing and neutralizing carbon impact.

Key Components:

- Calculate precise carbon footprint

- Invest in renewable energy projects

- Use carbon offset verified programs

- Partner with green shipping providers

- Transparent reporting

Certification Programs

- Climate Neutral Certified

- Green Business Bureau

- EPA SmartWay Partnership

- Carbon Trust Standard

5. Government Incentives: Your Financial Accelerator

Governments worldwide are encouraging sustainable practices through various incentives:

Potential Incentives:

- Tax credits for green vehicles

- Grants for sustainable infrastructure

- Reduced licensing fees

- Expedited permitting

- Lower insurance rates

Technology Integration Toolkit

Recommended Sustainability Tools:

- EcoVadis Sustainability Ratings

- Carbon Footprint Calculator

- Sustainability Performance Management Platforms

- Green Logistics Software

Implementation Roadmap

Conduct Sustainability Audit

- Measure current carbon footprint

- Identify improvement areas

- Set realistic goals

Develop Comprehensive Strategy

- Create phased implementation plan

- Budget for green investments

- Align with business objectives

Technology and Process Integration

- Select sustainable technologies

- Train team members

- Create green standard operating procedures

Continuous Improvement

- Quarterly sustainability reviews

- Stay updated on green technologies

- Encourage team innovation

Pro Tips for Transformation:

✅ Start small, think big

✅ Measure and celebrate progress

✅ Communicate your efforts

✅ Involve your entire team

✅ See sustainability as an opportunity

5 Essential FAQs: Reducing Logistics Expenses for Small Businesses in 2025

FAQ 1: What Are the Most Significant Hidden Costs in Small Business Logistics?

Hidden logistics costs are like silent budget killers that most small business owners overlook. The most significant expenses include:

- Inefficient routing (can consume 15-25% of transportation budget)

- Excess warehouse storage (potentially 10-20% of operational costs)

- Manual processing and administrative overhead

- Frequent small-batch shipping

- Ineffective inventory management

Average small businesses can save between $5,000 to $25,000 annually by systematically identifying and addressing these hidden expenses. The key is comprehensive audit and strategic optimization.

FAQ 2: How Can Technology Help Reduce Logistics Expenses?

Technology transforms logistics from a cost center to a strategic advantage. Critical technological interventions include:

- AI-powered route optimization tools (potential 20-35% transportation cost reduction)

- Cloud-based inventory management systems

- Real-time tracking platforms

- Predictive analytics for demand forecasting

- Automated shipping and processing software

Investing in the right technology can yield a return on investment (ROI) of 300-500% within the first 12-18 months, making it a game-changing strategy for small businesses.

FAQ 3: What Negotiation Strategies Work Best for Reducing Shipping Rates?

Effective shipping rate negotiation is an art and science that combines:

- Comprehensive shipping data analysis

- Understanding carrier pricing structures

- Leveraging shipping volume

- Exploring multiple carrier options

- Implementing strategic consolidation techniques

Small businesses with 100-500 yearly shipments can typically negotiate 10-20% rate reductions. The key is preparation, data-driven approaches, and willingness to explore alternative carriers.

FAQ 4: How Can Small Businesses Optimize Warehouse and Inventory Management?

Warehouse and inventory management optimization involves:

- Implementing just-in-time (JIT) inventory strategies

- Utilizing vertical storage solutions

- Adopting modular warehouse designs

- Leveraging predictive analytics

- Minimizing overstocking and understocking

Businesses can potentially improve warehouse space utilization by 25-40% and reduce inventory holding costs by 15-30% through strategic management and technology integration.

FAQ 5: What Sustainable Practices Can Help Reduce Logistics Expenses?

Sustainability isn’t just an environmental choice—it’s a strategic business decision that can significantly reduce expenses:

- Investing in energy-efficient vehicles

- Implementing efficient routing strategies

- Minimizing packaging waste

- Exploring carbon-neutral shipping options

- Leveraging government green incentives

Companies can potentially reduce operational costs by 20-45% while simultaneously improving brand reputation and attracting environmentally conscious customers.

Conclusion:

Reducing logistics expenses is an ongoing journey of strategic planning, technological integration, and continuous improvement. By implementing these six key strategies, small businesses can significantly cut costs, improve operational efficiency, and create a more competitive and sustainable logistics ecosystem.

Remember, every dollar saved in logistics is a dollar that can be reinvested in growth, innovation, and your company’s future. Start small, stay consistent, and watch your logistics expenses transform from a burden to a strategic advantage!

Ready to revolutionize your logistics spending? Begin by conducting a comprehensive cost audit and implementing one strategy at a time. Your bottom line will flourish!

If you are a small or medium company, you can ask for assistance to reduce the logistics cost as I have some great ideas that will be suitable for your business size. Contact me.